Electrical wires are the backbone of any electrical system. Whether you’re wiring a residential building, commercial office, or factory, the quality of the wire directly affects the safety and performance of the installation. For wholesalers and project managers, sourcing certified, high-performance wires is crucial.

Key Factors When Choosing Electrical Wires

-

Conductor Material

-

Copper is the most common and highly conductive

-

Aluminum is lighter and less expensive but has higher resistance

-

-

Insulation Type

-

PVC insulated wires for general purpose

-

XLPE wires for high-temperature environments

-

Fire-resistant cables for critical areas like hospitals or data centers

-

-

Wire Gauge and Load Capacity

Always choose the right wire size based on current load and voltage drop requirements. Undersized wires can overheat and cause electrical fires.

Common Types of Electrical Wires

-

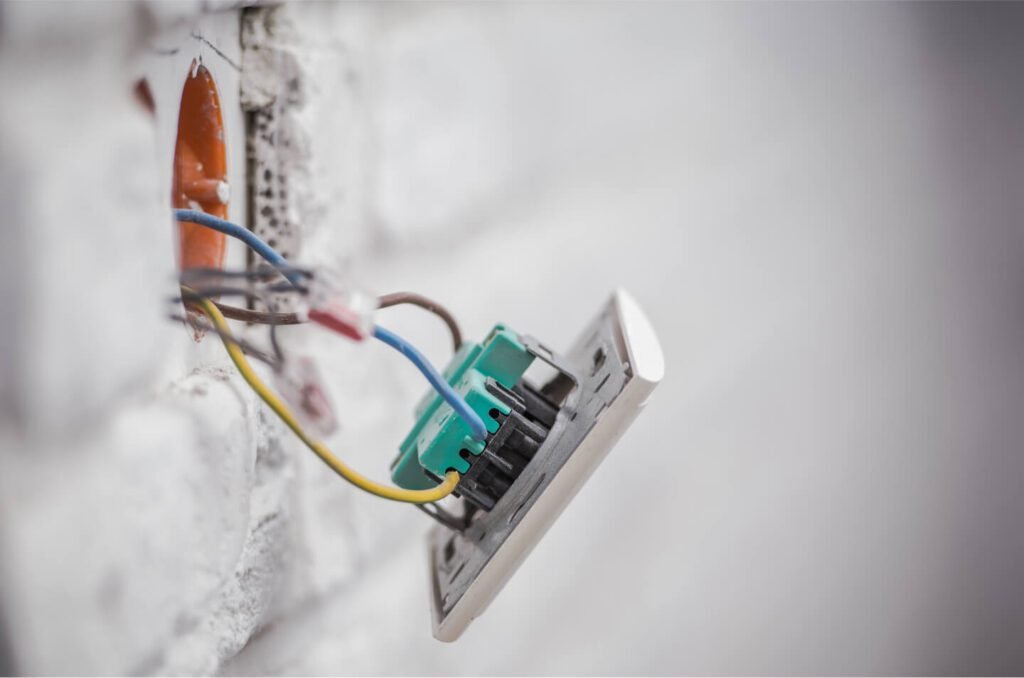

Single core wires – Used in home or light commercial applications

-

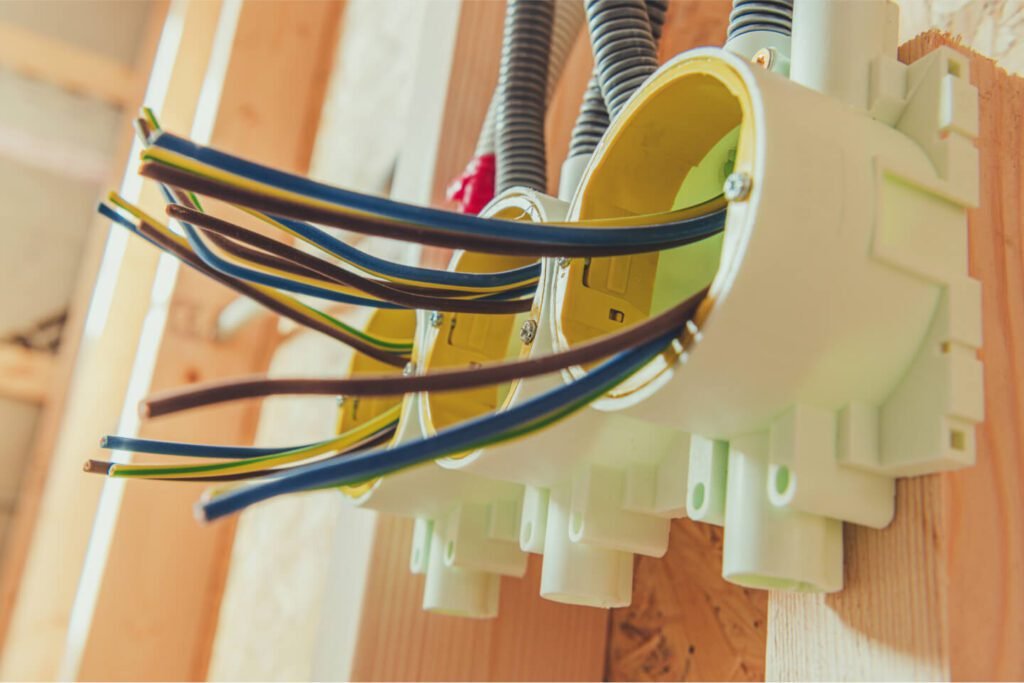

Multi-core cables – For control panels and industrial use

-

Flexible wires – Suitable for appliances and movable devices

-

Armored cables – Designed for underground or harsh environments

Why Certification Matters

Ensure wires comply with international safety and quality standards like IEC, UL, or BS. Proper labeling, testing, and manufacturing controls reduce risk and build trust with your customers.

Conclusion

Bulk electrical wire sourcing requires attention to quality, specifications, and manufacturer reliability. Partnering with a trusted electrical wire supplier ensures consistent product performance and customer satisfaction.